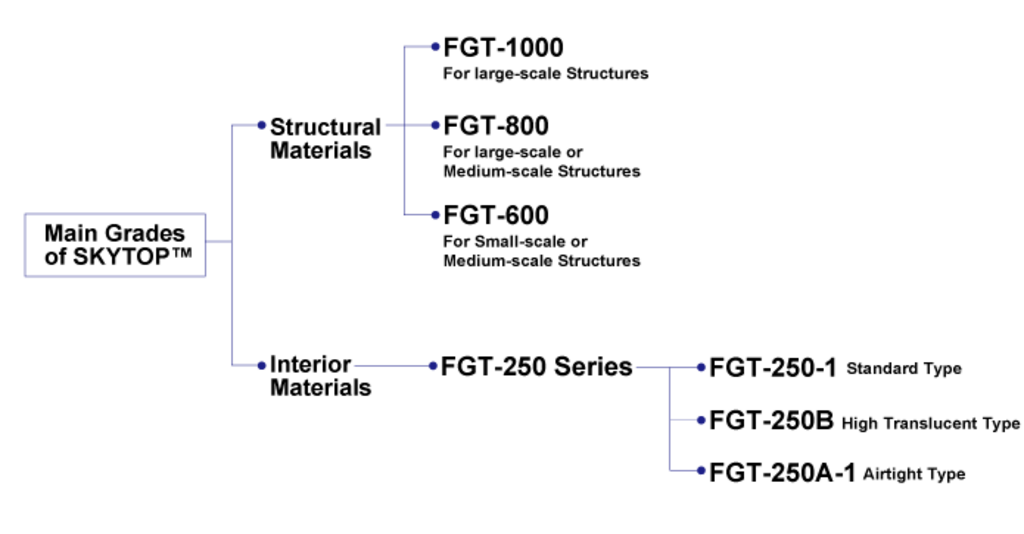

Architectural membrane material (SKYTOP™)

FGT Series

- Architectural membrane material (SKYTOP™)

overview

The FGT series is made by impregnating glass fiber B yarn cloth with fluoroplastic PTFE and baking it. B yarn has properties such as a specific strength superior to steel, heat resistance at 700-800℃, and not being affected by low temperatures or ultraviolet rays. In addition to heat resistance and Weatherability, fluoroplastic has unique properties such as non-stick characteristics does not allow things to stick to it, and water water repellent performance.

Applications

・Roofing materials

・Ceiling materials

・Interior materials

Operating temperature limit

-60°C to +260°C

structure

Features

non-flammability

fluoroplastic membrane material FGT series is a material that combines heat resistance glass cloth fiber and self-extinguishing PTFE.

For this reason, the FGT series is certified as a non-flammable material.

Self-cleaning

Dust and air pollutants that accumulate on the surface of fluoroplastic membrane materials are washed away with each rain, so there is no need for cleaning and the beauty of the material can be maintained for a long time.

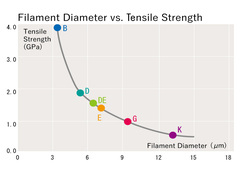

Resilience

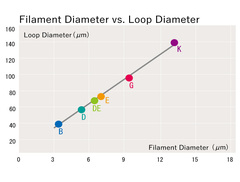

Generally, the smaller the diameter of the fiber, the higher the tensile strength per unit area. fluoroplastic material uses B yarn, the world's thinnest glass fiber, and is a membrane material with sufficient strength and high safety.

Sound absorption

The fluoroplastic membrane used as an interior material has moderate flexibility and air permeability, so when used as the inner membrane material in a double membrane structure, it can improve the acoustic effect inside a building.

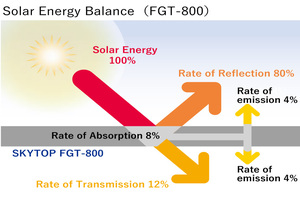

Translucency

Natural light entering the building through fluoroplastic membrane becomes naturally diffused light, creating a soft space with fewer shadows.

Thermal properties

Weatherability

It is not affected by ultraviolet rays or air pollution and maintains its functionality and safety as a roofing material for a long period of time.

Typical properties

| Product code | FGT-1000 | FGT-800 | FGT-600 | FGT-250-1 | FGT-250A-1 | FGT-250B | Test method | |

|---|---|---|---|---|---|---|---|---|

| Thickness (mm) (Median) |

1.00 | 0.80 | 0.60 | 0.35 | 0.40 | 0.23 | JIS K 6404-2-3 | |

| Mass (g/ m2) (Median) |

1700 | 1300 | 1000 | 470 | 600 | 250 | JIS K 6404-2-2 | |

| Tensile strength (N/3cm) (minimum value) |

Vertical | 5500 | 4410 | 3680 | 2400 | 2058 | 1176 | JIS L 1096 Cut Strip Method |

| side | 5000 | 3528 | 2940 | 1800 | 1568 | 980 | ||

| Elongation at break (%) (Median) |

Vertical | 6.0 | 5.0 | 5.0 | 4.0 | 3.0 | – | JIS L 1096 (Non-contact Elongation method) |

| side | 12.0 | 10.0 | 10.0 | 5.0 | 4.0 | – | ||

| Tear strength (N) (minimum value) |

Vertical | 400 | 294 | 225 | 153 | 127 | 59 | JIS L 1096 Trapezoid method |

| side | 450 | 294 | 225 | 96 | 98 | 59 | ||

| Visible light transmittance after bleaching (%) (Median) |

10 | 12 | 15 | 19 | 18 | 40 | JIS R 3106 (Spectrophotometer) |

|

| Visible light reflectance after bleaching (%) (Median) |

82 | 80 | 78 | 78 | 78 | 60 | JIS R 3106 (Spectrophotometer) |

|

| Ventilation measure (cm 3 /cm 2 ・s) (Median) |

– | – | – | 8 | – | 10 | JIS L 1096 (Fragile method) |

|

| Sound absorption coefficient (NRC) (Median) |

– | – | – | 0.45 | – | 0.45 | JIS A 1409 Reverberation Room Method |

|

Acquired Certifications

| Certification details | product name | Certification number | remarks |

|---|---|---|---|

| Building Materials | FGT-1000 FGT-800 FGT-600 |

MMEM-9029 | It has been certified by the Minister of Land, Infrastructure, Transport and Tourism as a designated building material as stipulated in Article 37, Paragraph 2 of the Building Standards Act. |

| Non-flammable materials | FGT-1000 FGT-800 FGT-600 |

NM-8665 | It has been certified by the Minister of Land, Infrastructure, Transport and Tourism as a non-combustible material as stipulated in Article 2, Clause 9 of the Building Standards Act. |

| FGT-250-1 FGT-250A-1 |

NM-8666 | ||

| FGT-250B | NM-0883 | ||

| FGT-250D | NM-3875 | ||

| Fire-retardant items | FGT-250-1 FGT-250A-1 FGT-250B |

A-13-0388 | This product is flame retardant certified by the Japan Fire Retardant Association. |

fluoroplastic material adoption record

You can see the track record of fluoroplastic materials.